SPC Aluminum Honeycomb Panel

Description

The SPC Aluminum Honeycomb Panel is a premium decorative panel that combines a high-performance SPC surface layer with a lightweight yet strong aluminum honeycomb core. It delivers the elegant texture of natural stone or wood while offering superior dimensional stability, water resistance, fire safety, and wear resistance.

This composite panel is an ideal alternative to traditional stone or wood materials in a variety of architectural and interior design applications.

Product Details

Structure

Top Surface: SPC Stone Plastic Decorative Layer

(Available in stone texture, wood grain, solid colors, matte/glossy finishes)

Core: Aluminum Honeycomb (6–25 mm hexagonal structure)

Back Layer: Aluminum sheet or custom balancing panel

Key Features:

Lightweight & High Strength – Easier to transport and install than traditional stone

Fire-Retardant – Meets Class B1 fire safety standard for public space use

Waterproof & Anti-Slip – Excellent performance in high-humidity and high-traffic areas

Wear-Resistant & Impact-Resistant – Durable surface suitable for floors and walls

Eco-Friendly – Formaldehyde-free, low VOC, non-toxic

Easy Customization – Cut-to-size, drilling, chamfering, or curved shaping supported

Dimensional Stability – Ideal for large-area cladding or flooring without warping

Technical Specifications:

Item | Specification |

SPC Surface Layer | Single SPC sheet: 1.2mm; Dual SPc sheet. 2.4mm |

Total Panel Thickness | 9–25 mm |

Core Material | Aluminum honeycomb |

Color | Customized colors according to customer requirements |

Standard Sizes | 1200×2400 mm / Custom sizes |

Surface Treatment | Pvc film |

PvC film effects | Solid color, brushed metal finish, mirror, anti-leather grain, wood grain, plain color, clothgrain |

Fire Rating | B (flame-retardant standard) |

Shape | Flat Plate |

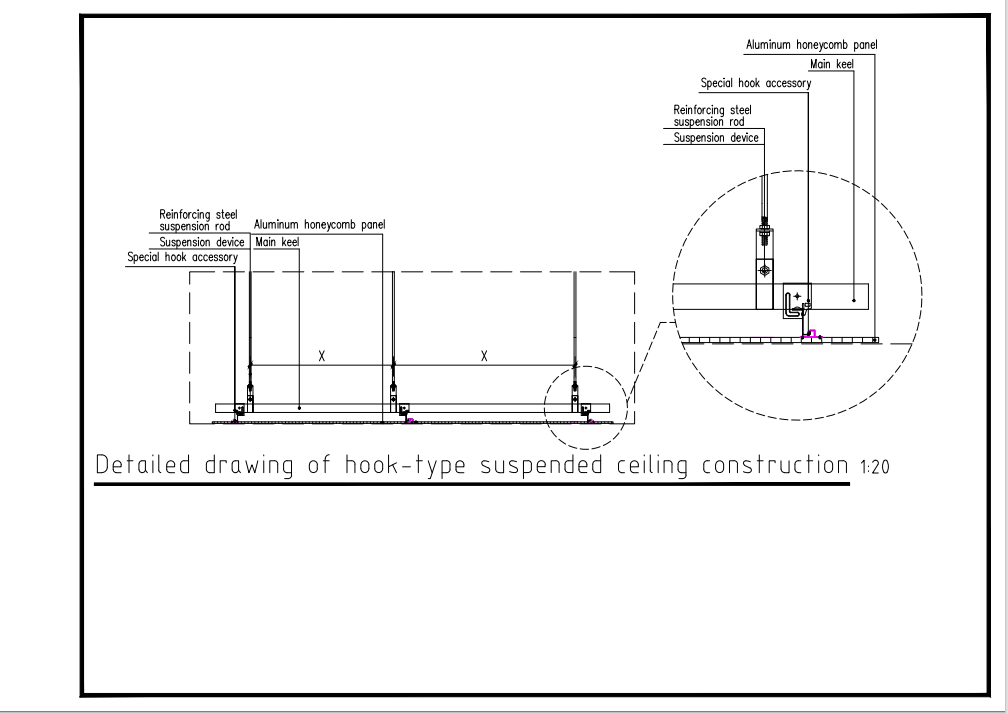

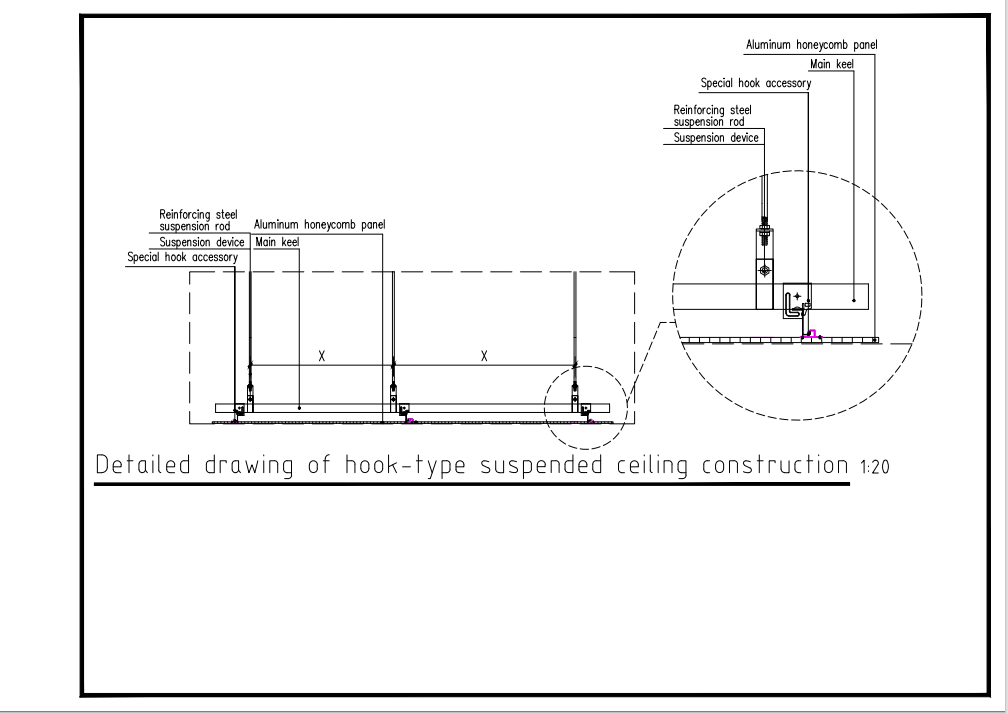

Installation Method | Bonding / Hook system / Mechanical fixings |

Application

Commercial interior flooring and wall cladding

Elevator cabins and wall panels

Clean rooms and medical facilities

High-end cabinet and furniture paneling

Exhibition spaces and decorative feature walls

Automotive, marine, or modular interiors

Automotive, marine, or modular interiors

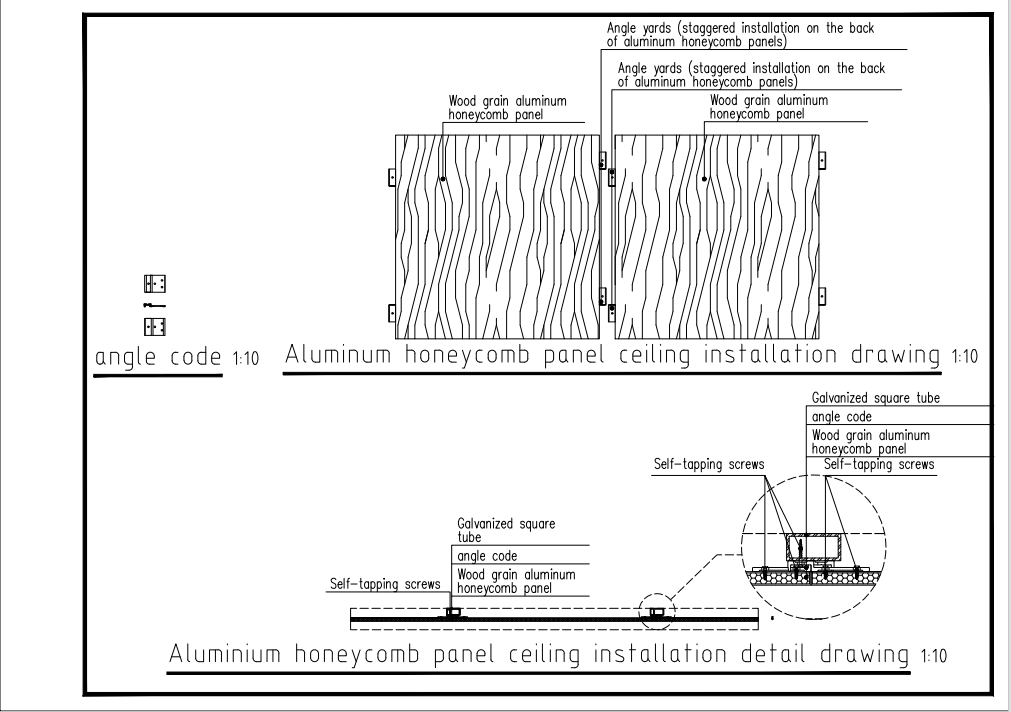

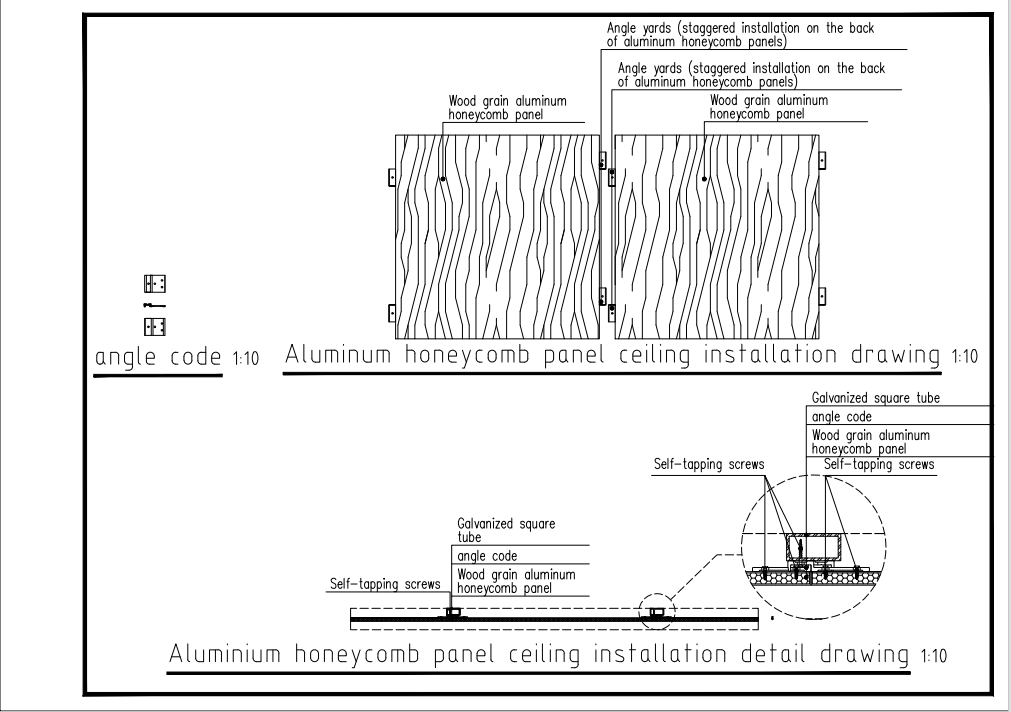

Installation method

Aluminum honeycomb panels are suitable for installation in dry hanging systems and exposed/dark keel structures. Supporting aluminum alloy hangers, pressure strips, sealants and other auxiliary materials are provided. It can also be installed by leveling the steel structure and fixing the corner code; the third method is to directly glue the wall after leveling.

Support professional installation guidance and drawing docking, engineering customers please contact customer service for docking solutions.

After Sales Service

OEM/ODM service

Pattern/color matching for large-scale projects

Technical drawings & installation guidance

Sample & small batch trial orders available

Contact us for product catalogs, samples, or personalized pricing. We are your trusted composite panel supplier for global projects!

FAQ

Q: What's the lead time for orders?

A: Standard models ship in 7-10 days; customized units require 15-20 days.

Q:What are the common specifications of your aluminum honeycomb panels? Can they be customized?

A:Our standard panel thicknesses include 7mm,9mm,10mm, 15mm, and 20mm, with regular sizes like 1220x2440mm. Customization is available for dimensions, surface materials (aluminum, PVDF, stainless steel, etc.), colors, and thickness according to your project needs.

Q:What are the main applications of aluminum honeycomb panels?

A:Aluminum honeycomb panels are widely used in building curtain walls, interior wall cladding, ceilings, ship interiors, rail transit, furniture panels, and display cabinets. They offer advantages such as lightweight, high strength, fire resistance, sound insulation, and thermal insulation.

Q:What is your Minimum Order Quantity (MOQ)? Do you offer samples?

A:The MOQ for standard products is 200 square meters. We can provide small samples for quality inspection. Sample costs and shipping fees are negotiable depending on the order.

Q:Do you offer OEM or ODM services?

A:Yes, we provide full OEM/ODM support. With our complete design, fabrication, and quality control systems, we can manufacture according to your drawings, specifications, or branding requirements.