High Strength Stone Honeycomb Sheet for Wall Cladding

Description

Stone honeycomb panels are advanced composite materials made by bonding a thin layer of natural stone (such as marble or granite) to a lightweight aluminum honeycomb core. This structure significantly reduces weight and improves strength, making it ideal for a wide range of architectural and decorative applications including exterior walls, interior cladding, elevators, yachts, and furniture.

Product Details

Structure

Surface Layer: Natural stone veneer (3–5 mm)

Core Material: Aluminum honeycomb core (hexagonal structure)

Back Panel: Aluminum sheet / fiberglass board / optional materials

Bonding Method: High-strength adhesive with hot or cold pressing process

Key Features:

Lightweight & High Strength

60–80% lighter than traditional solid stone, reducing structural load.

Impact-Resistant & Crack-Proof

Honeycomb structure enhances bending strength and anti-seismic performance.

Large Format & Flat Surface

Available in large sizes up to 1500×3000 mm with excellent flatness.

Easy Installation

Suitable for dry-hanging systems, aluminum frame systems, and modular assembly.

Eco-Friendly & Resource-Saving

Requires less natural stone, helping reduce environmental impact.

Customizable Stone Finishes

Compatible with marble, granite, artificial stone, quartz, and more.

Technical Specifications:

Item | Specification |

Stone Thickness | 3–8 mm |

Total Panel Thickness | 10–25 mm (customizable) |

Standard Size | 1200×2400 mm (Max: 1500×3000 mm) |

Honeycomb Cell Size | 6 mm / 8 mm / 10 mm |

Aluminum Foil Thickness | 0.05–0.08 mm |

Backing Options | Aluminum / Fiberglass / Stainless Steel / Stone |

Surface Treatment | Polished / Matte / Brushed / Anti-stain Coating |

Fire Rating | Class A2 (depending on panel composition) |

Application

Building curtain walls and interior wall decoration

Hotel, shopping mall, office building interior decoration and reception areas

Elevator cabins, subway stations, high-speed railway station decoration

Yachts, RVs, exhibition halls, and light-weight buildings

High-end cabinets, countertops, bathroom panels, and other furniture decoration

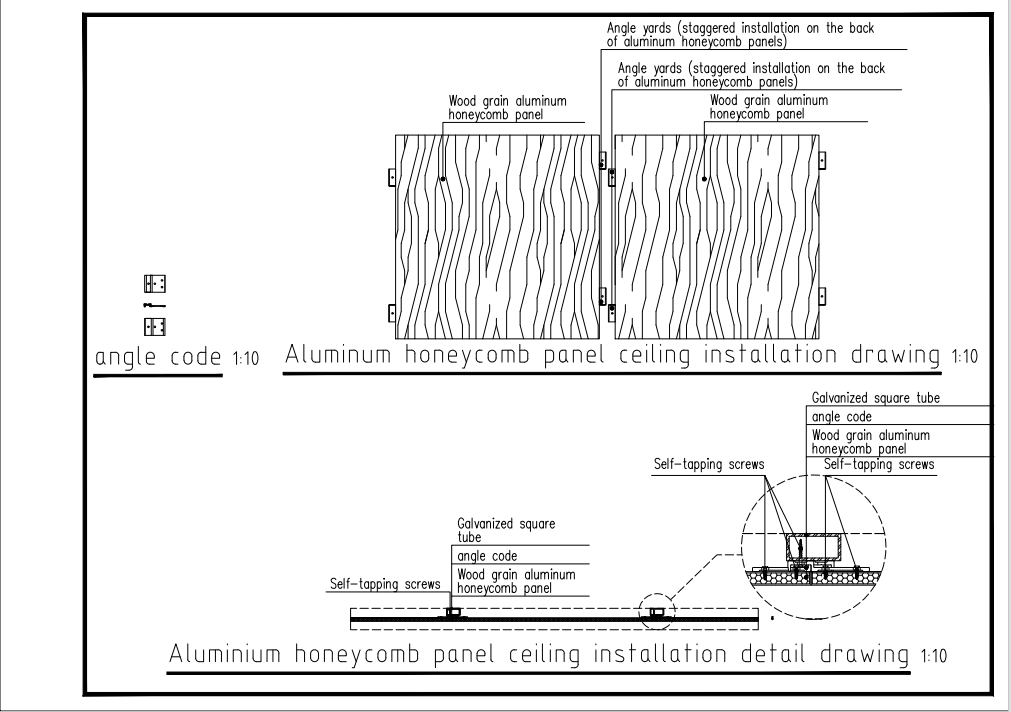

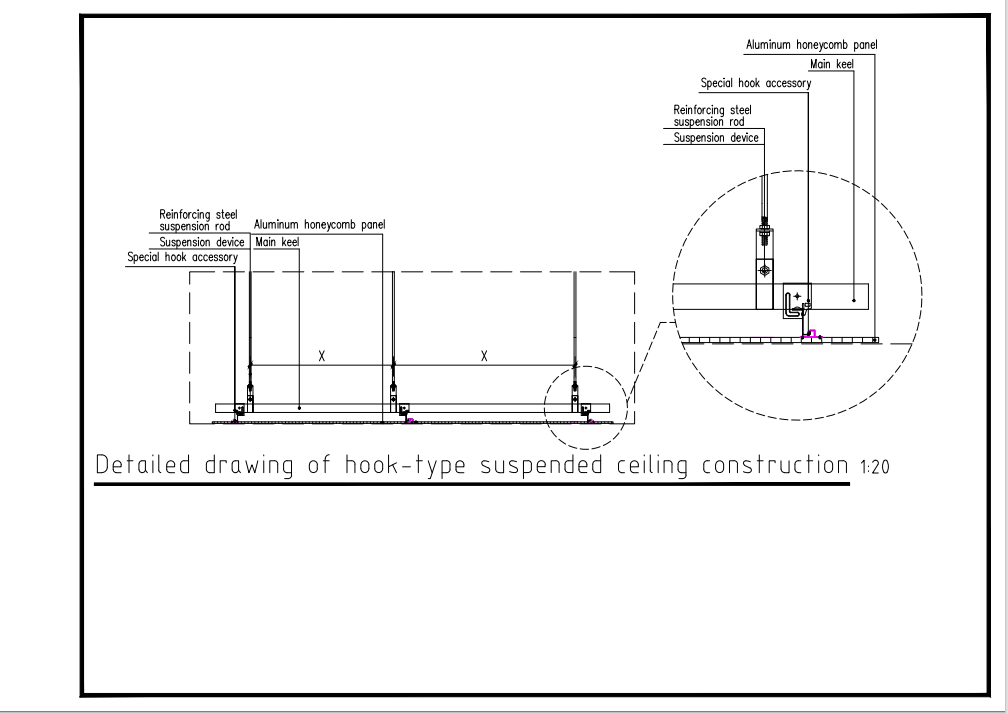

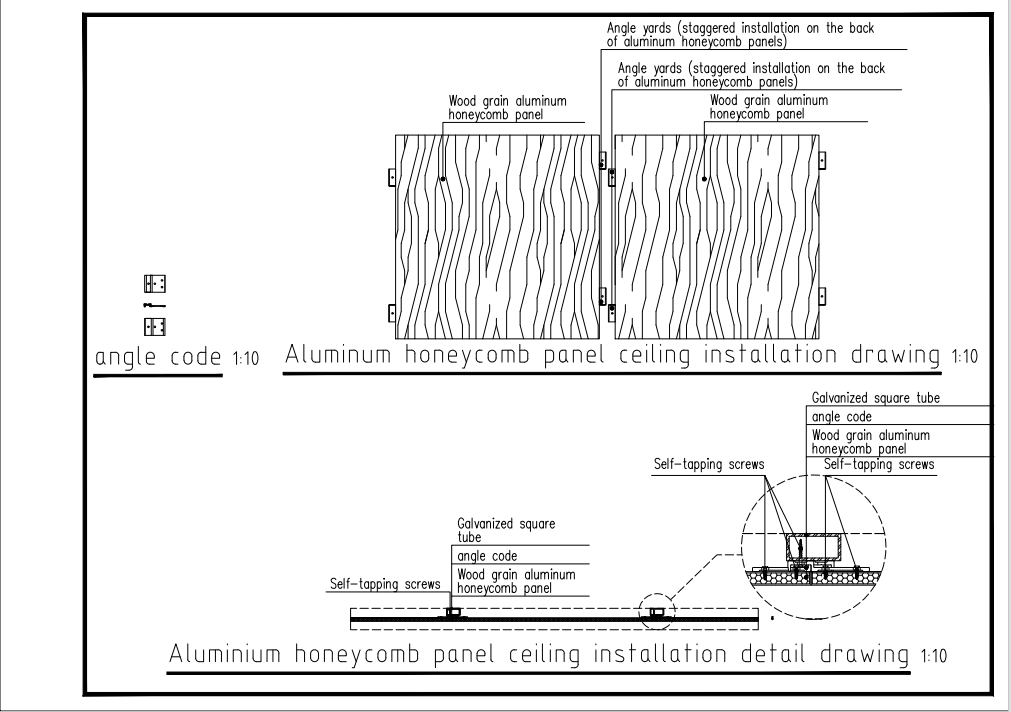

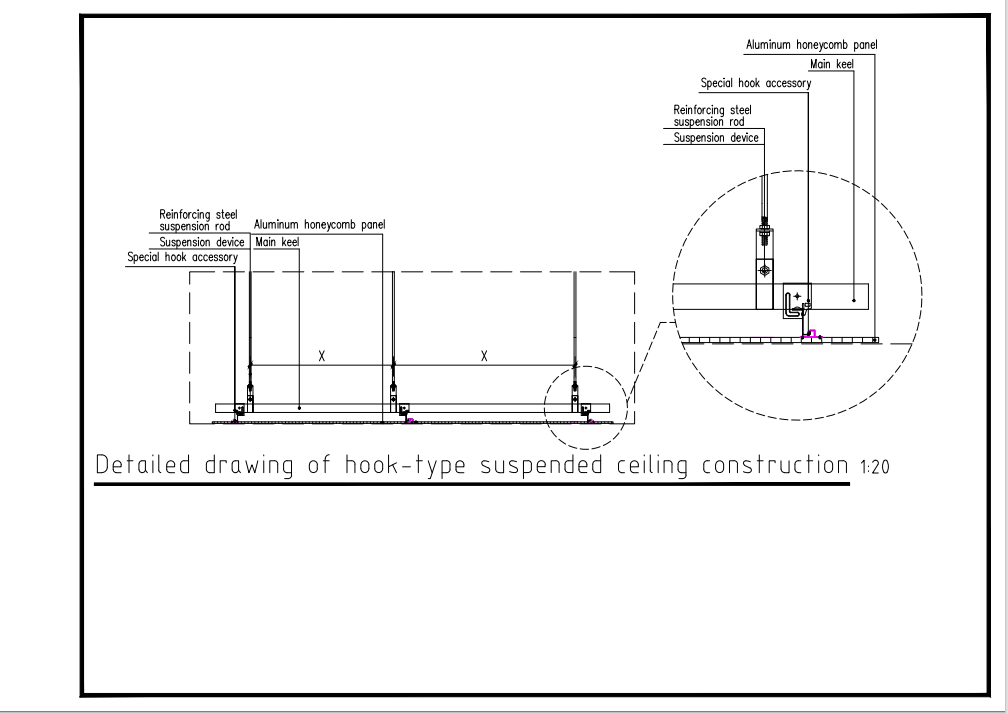

Installation method

Aluminum honeycomb panels are suitable for installation in dry hanging systems and exposed/dark keel structures. Supporting aluminum alloy hangers, pressure strips, sealants and other auxiliary materials are provided. It can also be installed by leveling the steel structure and fixing the corner code; the third method is to directly glue the wall after leveling.

Support professional installation guidance and drawing docking, engineering customers please contact customer service for docking solutions.

After Sales Service

OEM/ODM service

Wide selection of stone finishes

Technical support and CAD drawing compatibility

Sample provision and trial production

Global shipping support

Contact us for product catalogs, samples, or personalized pricing. We are your trusted composite panel supplier for global projects!

FAQ

Q: What's the lead time for orders?

A: Standard models ship in 7-10 days; customized units require 15-20 days.

Q:What are the common specifications of your aluminum honeycomb panels? Can they be customized?

A:Our standard panel thicknesses include 7mm,9mm,10mm, 15mm, and 20mm, with regular sizes like 1220x2440mm. Customization is available for dimensions, surface materials (aluminum, PVDF, stainless steel, etc.), colors, and thickness according to your project needs.

Q:What are the main applications of aluminum honeycomb panels?

A:Aluminum honeycomb panels are widely used in building curtain walls, interior wall cladding, ceilings, ship interiors, rail transit, furniture panels, and display cabinets. They offer advantages such as lightweight, high strength, fire resistance, sound insulation, and thermal insulation.

Q:What is your Minimum Order Quantity (MOQ)? Do you offer samples?

A:The MOQ for standard products is 200 square meters. We can provide small samples for quality inspection. Sample costs and shipping fees are negotiable depending on the order.

Q:Do you offer OEM or ODM services?

A:Yes, we provide full OEM/ODM support. With our complete design, fabrication, and quality control systems, we can manufacture according to your drawings, specifications, or branding requirements.