Soundproof Wood Veneer Honeycomb Panel for Interior Decoration

Description

Aluminum honeycomb panels are lightweight composite materials made of two aluminum sheets bonded to a honeycomb-shaped core. They offer high strength-to-weight ratio, rigidity, and good thermal and acoustic insulation. Commonly used in architecture, transportation, and aerospace, they provide structural efficiency and aesthetic appeal.

Product Details

Structure

Surface technology: film lamination, spraying, roller coating

Core Material: Aluminum honeycomb core (hexagonal structure)

Panel material: aluminum plate (commonly 0.7mm ~ 2mm thick)

Backboard material: aluminum plate

Bonding technology: aviation-grade adhesive, hot pressing composite technology

Key Features:

Lightweight and high strength: The honeycomb structure makes the weight of the plate only one-third of the solid aluminum plate of the same thickness.

Fireproof and moisture-proof: All-aluminum material, non-flammable, moisture-proof, corrosion-resistant, suitable for various complex environments.

Sound insulation and heat insulation: The hollow structure greatly reduces heat conduction and noise transmission.

Smooth surface: Strong anti-deformation ability, suitable for large-area curtain walls and interior decoration.

Environmentally friendly and healthy: No formaldehyde release, green and environmentally friendly materials.

High cost performance: Both structural strength and decorativeness, easy installation, and cost saving.

Customizable: size, and surface material can be customized as needed.

Technical Specifications:

Item | Parameter Description |

Product Name | All-aluminum honeycomb panel |

Regular size | 1220×2440mm,1200×2800 (customization supported) |

Thickness range | 7mm ~ 30mm |

Panel thickness | 0.7mm ~ 2mm aluminum plate |

Honeycomb core specifications | Side length 3mm~10mm |

Aluminum foil thickness | 0.035mm ~ 0.1mm |

Panel material | 3003/5052 aluminum alloy |

Surface treatment | Film/fluorocarbon spraying/powder spraying/anodizing, etc. |

Fireproof grade | A2/B1 (according to GB8624 standard) |

Application

Building curtain wall facades

High-end interior walls and ceilings

Medical/education/office/commercial spaces

High-speed rail/subway/airport/exhibition hall interiors

Furniture door panels, cabinet back panels, display cabinet back walls

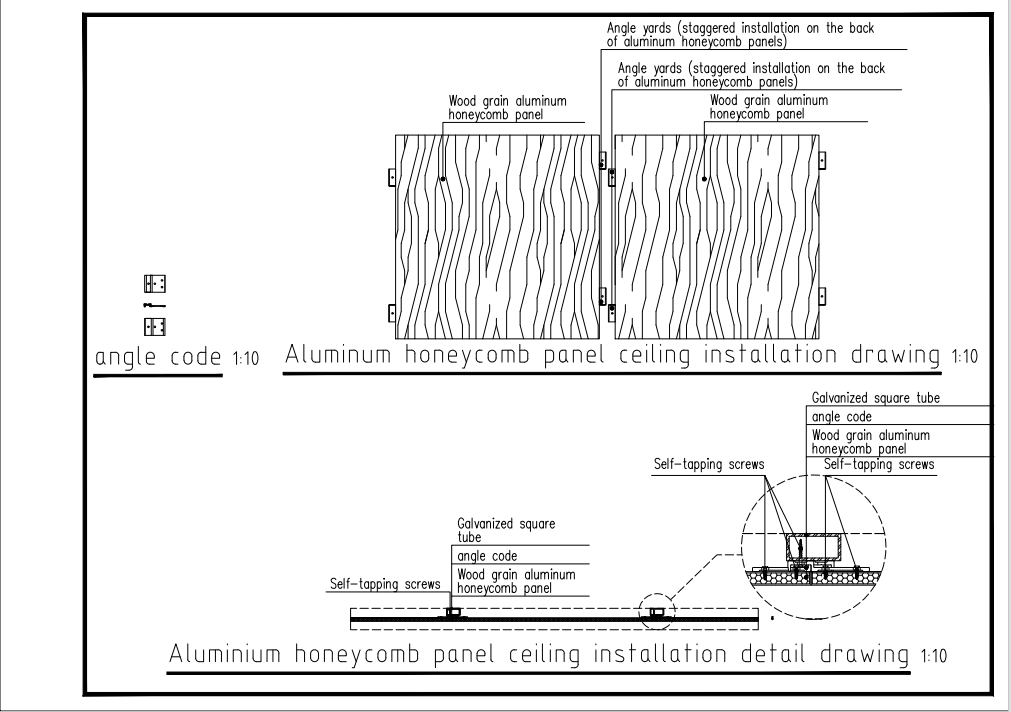

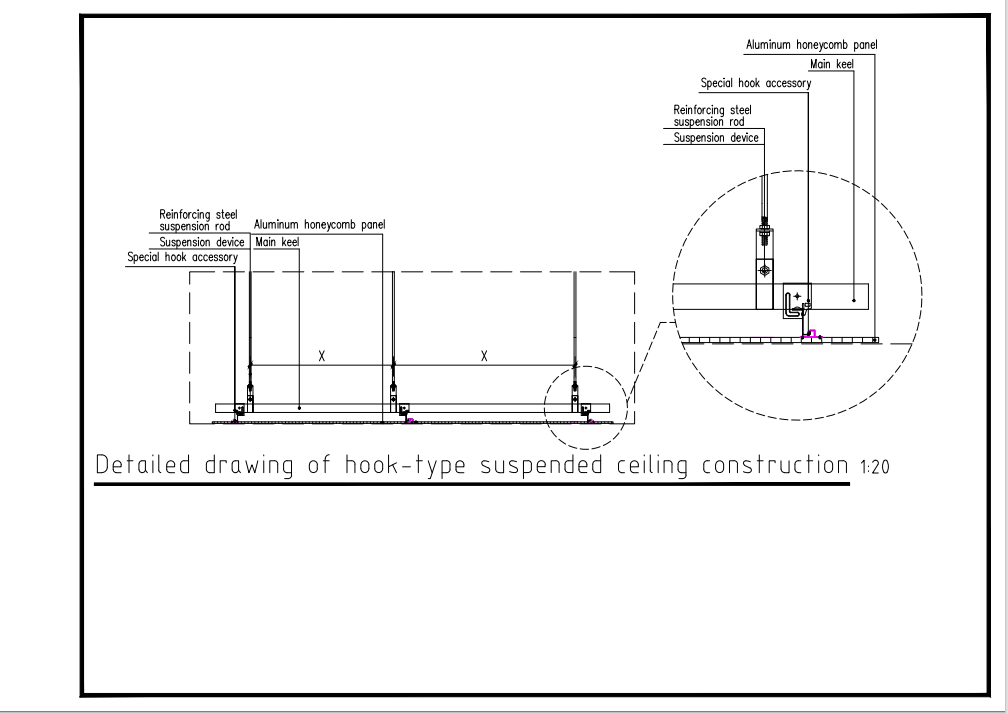

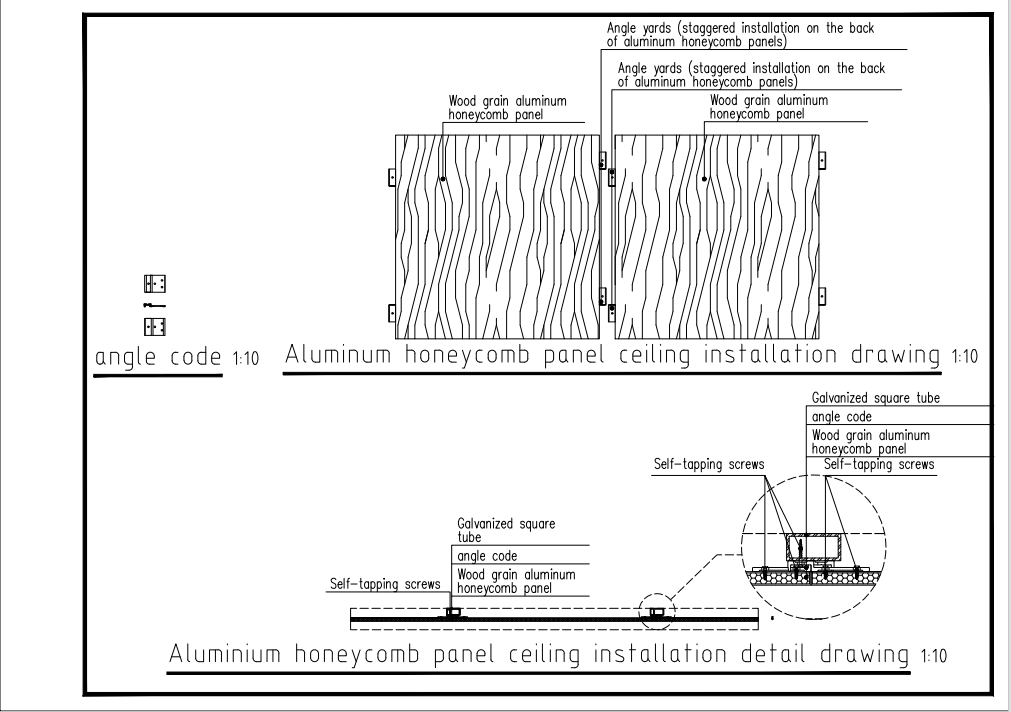

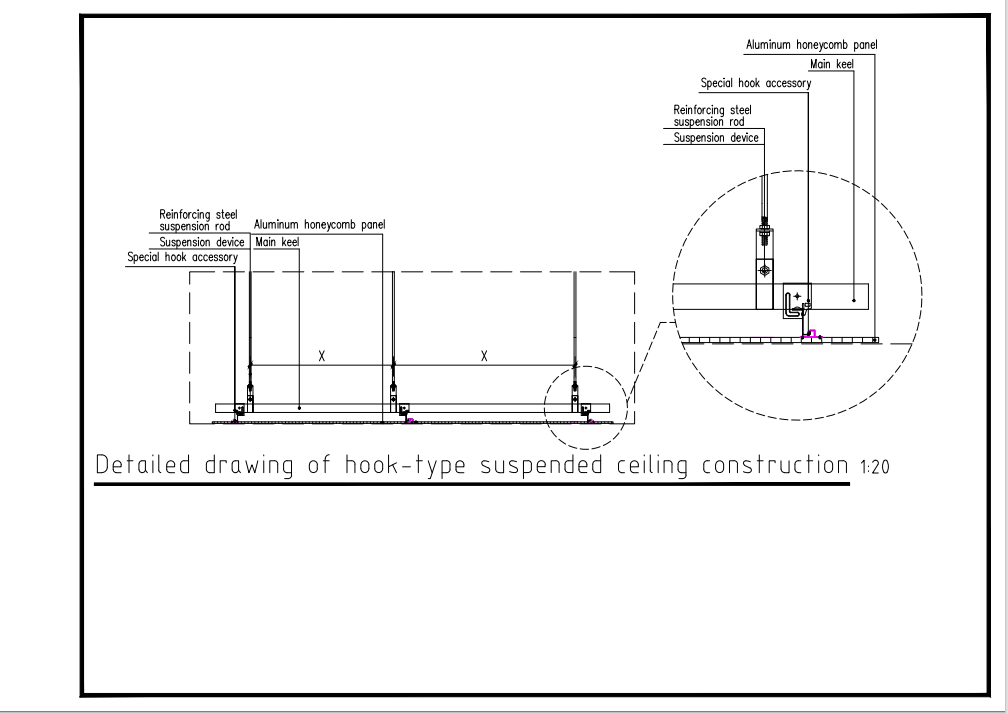

Installation method

Aluminum honeycomb panels are suitable for installation in dry hanging systems and exposed/dark keel structures. Supporting aluminum alloy hangers, pressure strips, sealants and other auxiliary materials are provided. It can also be installed by leveling the steel structure and fixing the corner code; the third method is to directly glue the wall after leveling.

Support professional installation guidance and drawing docking, engineering customers please contact customer service for docking solutions.

After Sales Service

Minimum order quantity: calculated according to the size of the board (usually ≥200 square meter)

Delivery period: 7-10 days for regular models, 15-20 days for customized models

Delivery method: wooden frame packaging, direct logistics

Supporting services: provide CAD in-depth design, construction guidance, sample delivery

Contact us for product catalogs, samples, or personalized pricing. We are your trusted composite panel supplier for global projects!

FAQ

Q: What's the lead time for orders?

A: Standard models ship in 7-10 days; customized units require 15-20 days.

Q:What are the common specifications of your aluminum honeycomb panels? Can they be customized?

A:Our standard panel thicknesses include 7mm,9mm,10mm, 15mm, and 20mm, with regular sizes like 1220x2440mm. Customization is available for dimensions, surface materials (aluminum, PVDF, stainless steel, etc.), colors, and thickness according to your project needs.

Q:What are the main applications of aluminum honeycomb panels?

A:Aluminum honeycomb panels are widely used in building curtain walls, interior wall cladding, ceilings, ship interiors, rail transit, furniture panels, and display cabinets. They offer advantages such as lightweight, high strength, fire resistance, sound insulation, and thermal insulation.

Q:What is your Minimum Order Quantity (MOQ)? Do you offer samples?

A:The MOQ for standard products is 200 square meters. We can provide small samples for quality inspection. Sample costs and shipping fees are negotiable depending on the order.

Q:Do you offer OEM or ODM services?

A:Yes, we provide full OEM/ODM support. With our complete design, fabrication, and quality control systems, we can manufacture according to your drawings, specifications, or branding requirements.