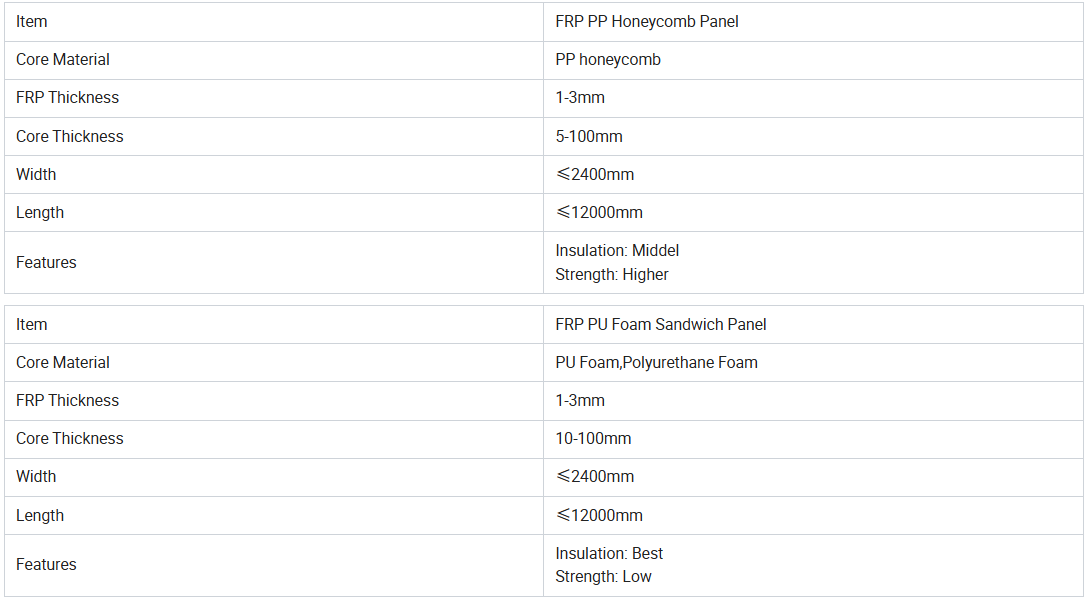

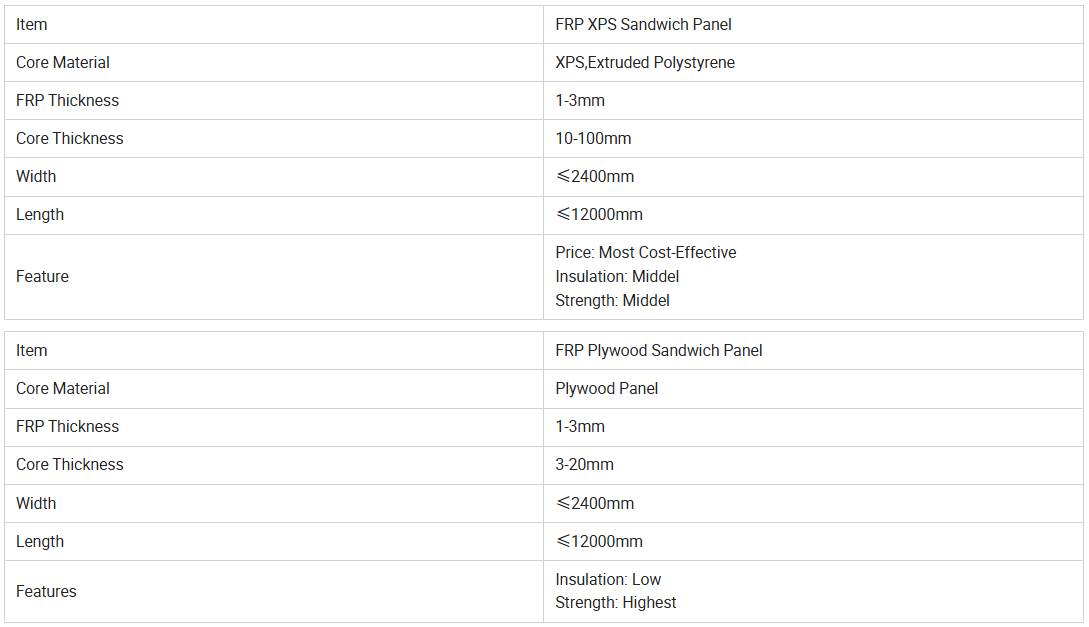

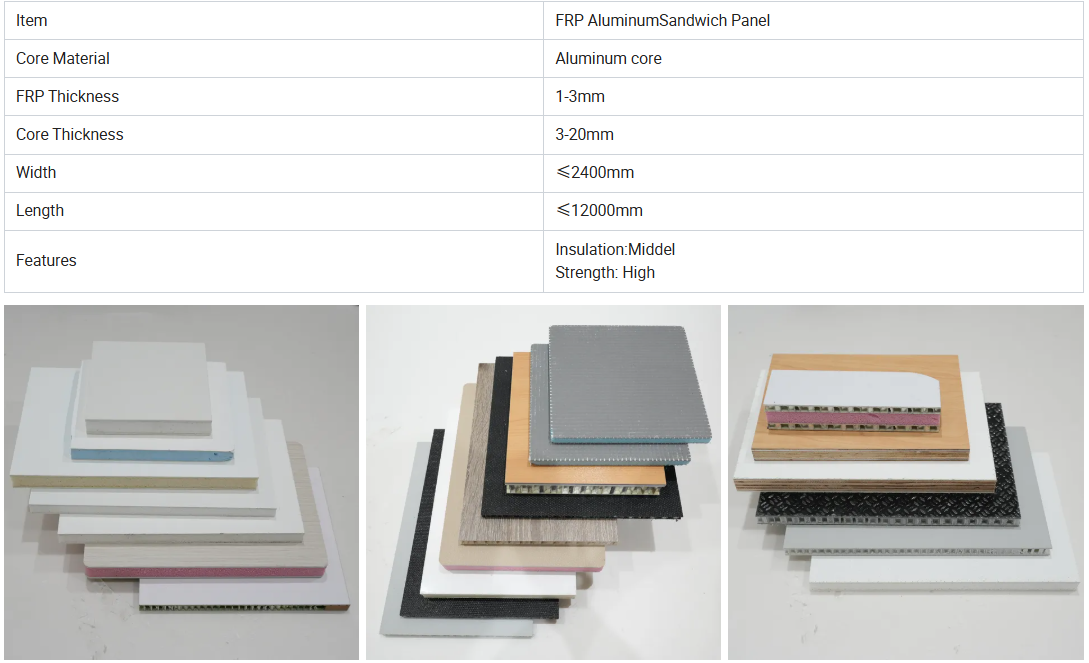

FRP is fiberglass reinforced plastic which is a high strength, durable and chemical resistant material. And the FRP surface can be gel coated surface or rough surface without gel coat. While the honeycomb core can be PP, PU, XPS, EPS, Plywood, etc honeycomb core. And FRP honeycomb panel is used for vast applications, mainly for dry van truck body, building partition walls and substrate panel to glue stone or porcelain tiles etc.

To enhance the safety and longevity of our composite panels, we incorporate flame retardants and anti-aging agents. These additives significantly improve the panels' resistance to fire and deterioration over time.

For specific FRP XPS composite panels requiring enhanced structural integrity, we integrate reinforced materials such as timber, aluminum tubes, FRP tubes, and high-strength plastic bars. This reinforcement is strategically embedded within the panels to bolster their strength and durability.

Our CNC Processing Service offers precision cutting, drilling, and grinding of composite panels according to your exact specifications and blueprints. This service ensures that each panel meets the highest standards of quality and fits perfectly within your project's requirements.